Авторизация

Сейчас на сайте

Счетчики

Frames что это такое - шпангоуты?

Frames

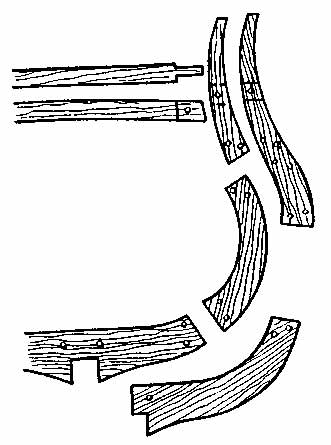

Frames together with beams are made from one piece of plywood. Drawing them on plywood requires great care. It should be remembered that the dimensions of the frames are given taking into account the thickness of the skin. On the drawing of the frame, tracing paper is applied, the center line and the outer edge of the frame are drawn minus the thickness of the skin. The width of the frames should be taken 10 - 12 mm, above the keel - a little more.

Frames together with beams are made from one piece of plywood. Drawing them on plywood requires great care. It should be remembered that the dimensions of the frames are given taking into account the thickness of the skin. On the drawing of the frame, tracing paper is applied, the center line and the outer edge of the frame are drawn minus the thickness of the skin. The width of the frames should be taken 10 - 12 mm, above the keel - a little more.

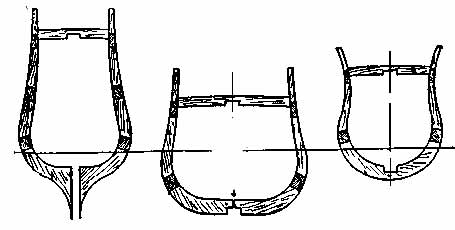

Beams and frames form one whole. The height of the beams is about 6 mm, and the thickness of the deck, about 2 - 2.5 mm, must be subtracted when drawing. The upper deck, just like on a real ship, must be destroyed. The chord height of the bulge is 1 mm for every 50 mm of the beam length.

Since this curve, which is a part of the circumference, is repeated on all beams, it is most convenient to make a template for drawing it. To give the deck more rigidity, triangles - knits are left on the frames on both sides, under the beams.

Beams in the case when it is under some hole in the deck, cut through. If the model is two- or three-deck, then one or two more rows of beams should be located under the upper deck on the frames. On each frame, it is necessary to mark the constructive waterline and the lower or upper edge of the velvet.

After half of the frame is applied to the tracing paper, including the center line, the notches for the keel frame and the corresponding frame number, the tracing paper is applied to the plywood, where, using copy paper, this software is transferred half of the frame. Then they turn the tracing paper around the middle line and draw the second half. This operation is repeated every drawing! about the frame.

After that, the frames are cut out with a jigsaw. By folding the frames in sequence one by one, the future, albeit compressed, shape of the hull can be seen. All frames, with the exception of the front ones, have a cut at the bottom for attaching them to the keel frame from above, while the front frames on the keel frame are fitted from below and therefore have a cut in the beam.

When assembling, carefully pushing the cut apart, the frames are put on the keel frame. Then it is installed on the slipway and each frame is carefully glued. If gaps are formed between the frame and the keel frame, then they are filled with cardboard of the appropriate thickness so that excessive stress is not created in the frames. When installing the frames, make sure that they are perpendicular to the slipboard and that the waterline marks on their sides are at the same height relative to the slipboard. This height is best checked with a ruler or thin staff. Then it is advisable to nail each frame with a few thin studs.

When assembling, carefully pushing the cut apart, the frames are put on the keel frame. Then it is installed on the slipway and each frame is carefully glued. If gaps are formed between the frame and the keel frame, then they are filled with cardboard of the appropriate thickness so that excessive stress is not created in the frames. When installing the frames, make sure that they are perpendicular to the slipboard and that the waterline marks on their sides are at the same height relative to the slipboard. This height is best checked with a ruler or thin staff. Then it is advisable to nail each frame with a few thin studs.

For further reinforcement of the hull, wooden blocks are glued between the individual frames at the height of the decks, as well as where the channels will later be attached. These blocks must be equal in length to the spacings. Similar rows of bars can be placed between the frames at the upper deck and in the keel area. As a result, the body becomes more rigid.

After assembling the frames, the transom is attached. Since the sternpost protruded above the transom, it is better to make the latter from two halves. Along the deck, the transom was slightly curved, approximately the same as the beams. It had cannon ports and hatches. The boards, of which the transom consisted, can be depicted with notches, passing them obliquely downward from the stem. The transom is attached to the last frame, and on the keel frame it is fixed by means of strips on both sides of the stem. In the same way, a valance with a hole for a tiller is installed.

Шпангоуты

Каркасы вместе с балками изготавливаются из одного куска фанеры. Каркасы вместе с балками изготавливаются из одного куска фанеры. Рисование их на фанере требует большой осторожности. Следует помнить, что размеры рамок даны с учетом толщины кожи. На чертеж каркаса накладывается калька, чертится центральная линия и внешний край каркаса за вычетом толщины кожи. Ширину шпангоутов следует брать 10 – 12 мм, над килем – немного больше.

Балки и рамы образуют одно целое. Высота балок около 6 мм, а толщину настила, около 2 – 2,5 мм, при чертеже необходимо вычесть. Верхняя палуба, как и на настоящем корабле, должна быть разрушена. Высота хорды выпуклости составляет 1 мм на каждые 50 мм длины балки.

Поскольку эта кривая, являющаяся частью окружности, повторяется на всех балках, удобнее всего сделать шаблон для ее нанесения. Для придания настилу большей жесткости на шпангоутах с обеих сторон, под балками, оставляют треугольники – вязалки.

Балка в том случае, когда она находится под каким-то отверстием в палубе, прорезается насквозь. Если модель двух- или трехпалубная, то под верхней палубой на шпангоутах следует расположить еще один или два ряда балок. На каждом шпангоуте необходимо отметить конструктивную ватерлинию и нижний или верхний край бархата.

После того, как на кальку нанесена половина шпангоута, включая центральную линию, выемки для килевого шпангоута и соответствующий номер шпангоута, калька прикладывается к фанере, куда с помощью копировальной бумаги этим программным обеспечением переносится половина рама. Затем переворачивают кальку вокруг средней линии и рисуют вторую половину. Эта операция повторяется в каждом рисунке! о рамке.

После этого лобзиком вырезаются рамки. Складывая шпангоуты последовательно один за другим, можно увидеть будущую, хоть и сжатую, форму корпуса. Все шпангоуты, за исключением передних, имеют внизу прорезь для крепления их к килевому шпангоуту сверху, тогда как передние шпангоуты на килевом шпангоуте подгоняются снизу и поэтому имеют вырез в балке.

После того как на кальку прикладывается половина шпангоута, включая центральную линию, при сборке, аккуратно раздвинув разрез, шпангоуты надеваются на килевой шпангоут. Затем его устанавливают на стапель и тщательно проклеивают каждый шпангоут. Если между шпангоутом и килевым каркасом образуются зазоры, то их заполняют картоном соответствующей толщины, чтобы в шпангоутах не создавались чрезмерные напряжения. При установке шпангоутов следите за тем, чтобы они были перпендикулярны доске и чтобы отметки ватерлинии на их сторонах находились на одной высоте относительно доски. Эту высоту лучше всего проверять линейкой или тонкой рейкой. Затем желательно каждую рамку прибить несколькими тонкими гвоздиками.

Для дальнейшего усиления корпуса между отдельными шпангоутами на высоте палуб, а также там, где в дальнейшем будут крепиться швеллеры, вклеиваются деревянные бруски. Длина этих блоков должна быть равна расстояниям. Подобные ряды брусьев можно разместить между шпангоутами на верхней палубе и в районе киля. В результате тело становится более жестким.

После сборки шпангоутов крепится фрамуга. Поскольку ахтерштевень выступал над транцем, последний лучше сделать из двух половин. По палубе транец был слегка изогнут, примерно так же, как и бимсы. Он имел пушечные порты и люки. Доски, из которых состоял фрамуга, можно изобразить с насечками, проходя их наискосок вниз от форштевня. К последнему шпангоуту крепится транец, а на килевом шпангоуте он закрепляется посредством планок с обеих сторон форштевня. Таким же образом устанавливается подзор с отверстием для румпеля.

****

Letzte Kommentare

Artikel

Fotos

Eigene Seiten